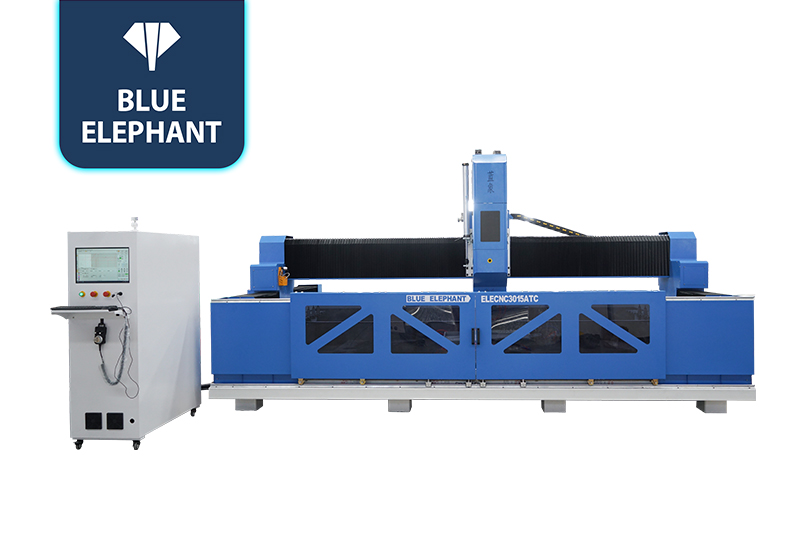

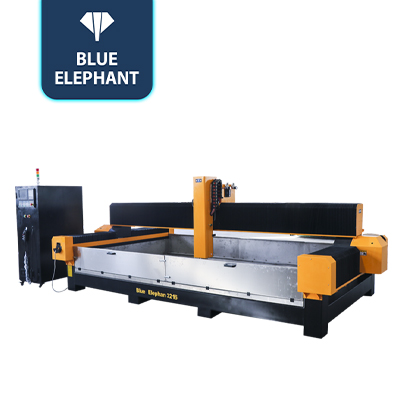

Affordable ATC Quartz Stone Machining Center for Making Stone Countertops

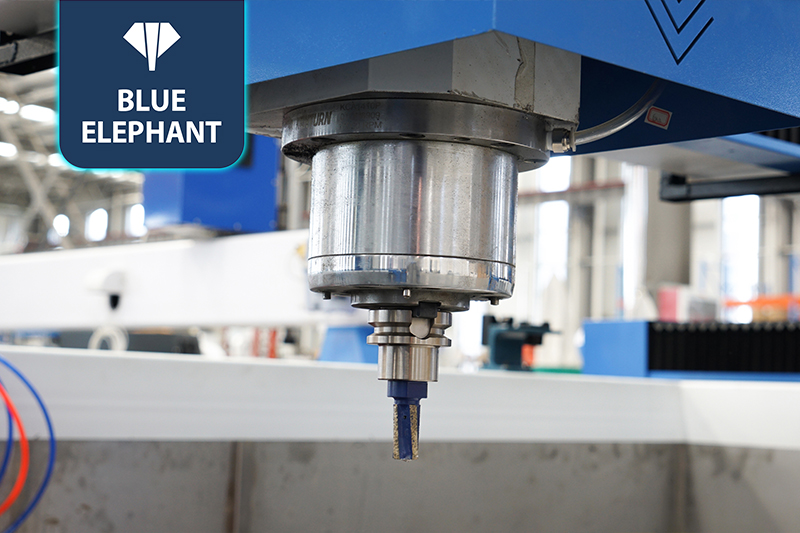

It adopts the Kenturn mechanical spindle, with low speed and big torque. The spindle can spray water in the middle, very suitable for stone processing.Rigid phenolic board tabletop has such features as high strength, strong adsorption, chemical resistance, impact resistance, abrasion resistance, easy to clean, fireproof, heat-resistant, and smoke-resistance.

Stone Engraving Machines Video

Parameters

| Working area | 3000x1500x400mm |

| Spindle | KCA1410P-CTS spindle |

| Spindle speed | 10000RPM |

| Tool magazine | Linear tool magazine with 12 tools |

| Control system | NC60A control system for stone machine |

| Motor and driver | Japan YASKAWA servo motor, 7.5kw CTB servo motor for spindle |

| Working Table | Phenolic board hard table, equipped with 8 suction cups |

| Tool holder | BT40 tool holder |

| Reducer | Japan Shimpo reducer/ |

| Lubrication system | Automatic lubrication |

| Voltage | 380V, 50Hz, 3 phase |

| X,Y,Z Transmission | Helical rack gears transmission on X, Y axis, Taiwan TBI ball screw transmission on Z axis |

| X,Y,Z Rail | Taiwan PMI linear guide rails, #35 for Y axis, #30 for XZ axis |

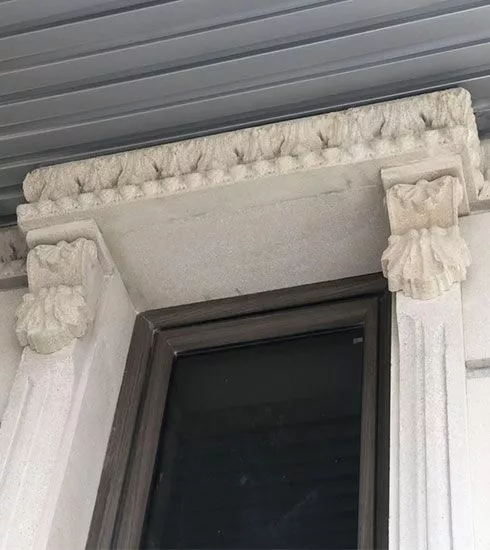

Application

Stone CNC engraving machine is mainly designed to deal with stone work such as line carving, 2D plane carving, 3D relief carving, shadow carving, etc. It can process marble, granite, jade, crystal, tombstone, agate, ceramic, plastic, chemical composite board, and other materials. It is widely used in processing marble and granite kitchen countertops, bathroom countertops, wash basins, tables, drain tanks, etc.

Production Facility

Quality Control & Testing